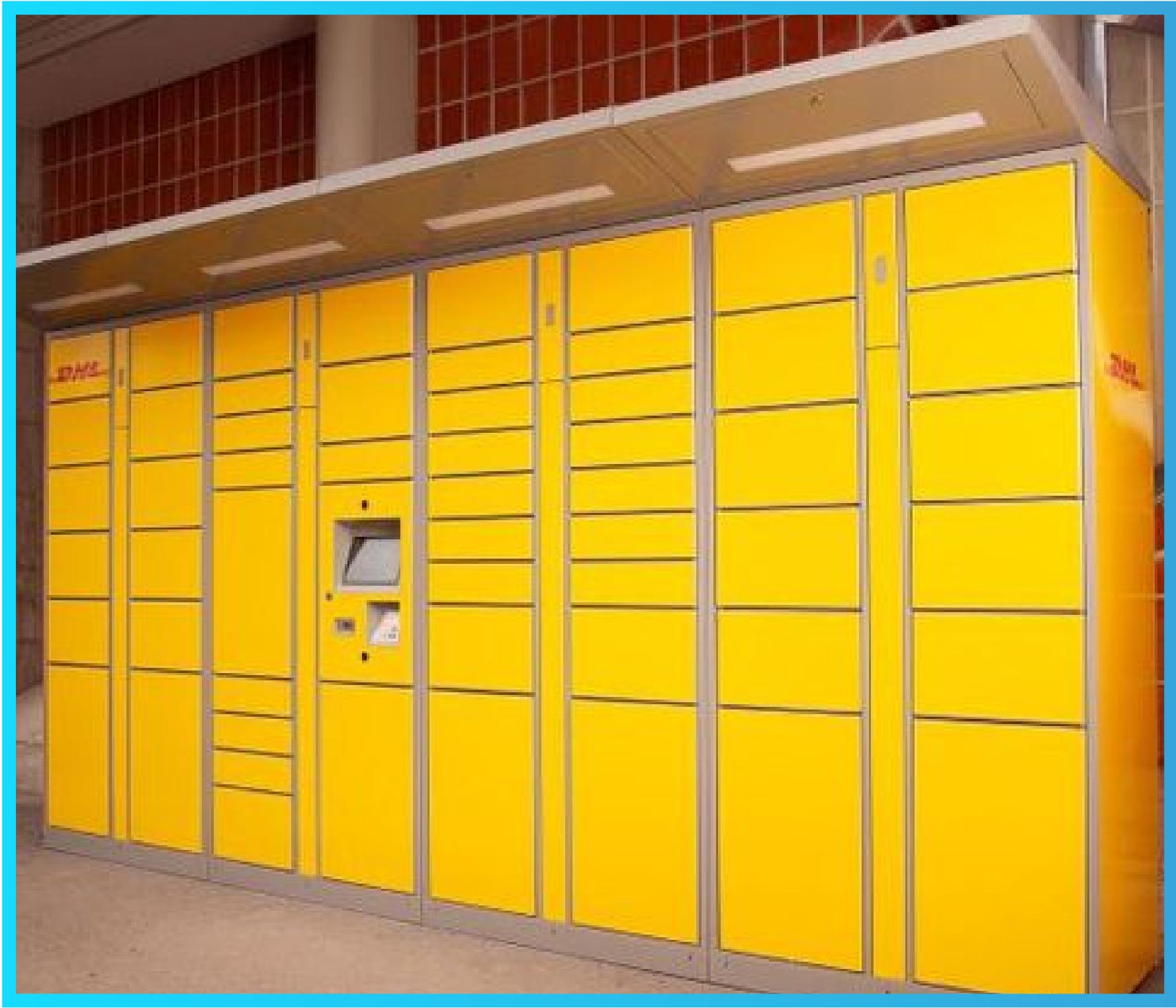

Digital engine - the intelligent center of factory logistics

__________

The intelligent transceiver system integrates software and hardware to realize digital management, efficiently meet the needs of letter/parcel sending, logistics scheduling, and information publicity in industrial parks, and drive the intelligent operation and upgrading of factories with technological innovation.

Digital management improves efficiency: online processes replace manual registration, and the sending and receiving status is synchronized in real time.

Deep coverage of scenarios: suitable for production workshops, logistics warehouses, administrative office buildings and other areas.

Technology empowers transformation: Internet of Things intelligent identification, opening up data in all aspects of logistics.

Safety control - factory operation protection net

__________

The intelligent transceiver system integrates security supervision modules, unifies data center management, links factory security and fire protection systems, ensures the safety of logistics links, and quickly responds to abnormal events.

Unified data supervision: The whole process of equipment status and sending and receiving records can be checked.

Security scenario coverage: abnormal pick-up warning, dangerous goods identification.

Emergency linkage response: Connect with the security system and provide second-level early warning of abnormal situations.

Efficient collaboration – the engine of acceleration in production logistics

__________

It supports time-sharing sending and receiving planning, multi-terminal information linkage (factory large screen, employee side, logistics vehicle machine), realizes dynamic resource scheduling and real-time data monitoring, and improves the efficiency of logistics operations in the park.

Time-sharing operation planning: off-peak delivery/pick-up to avoid production peaks.

Multi-terminal data collaboration: Logistics progress is synchronized to the workshop kanban and employee mobile phones.

Data-based supervision: logistics efficiency analysis, equipment load statistics, and optimization of resource allocation.

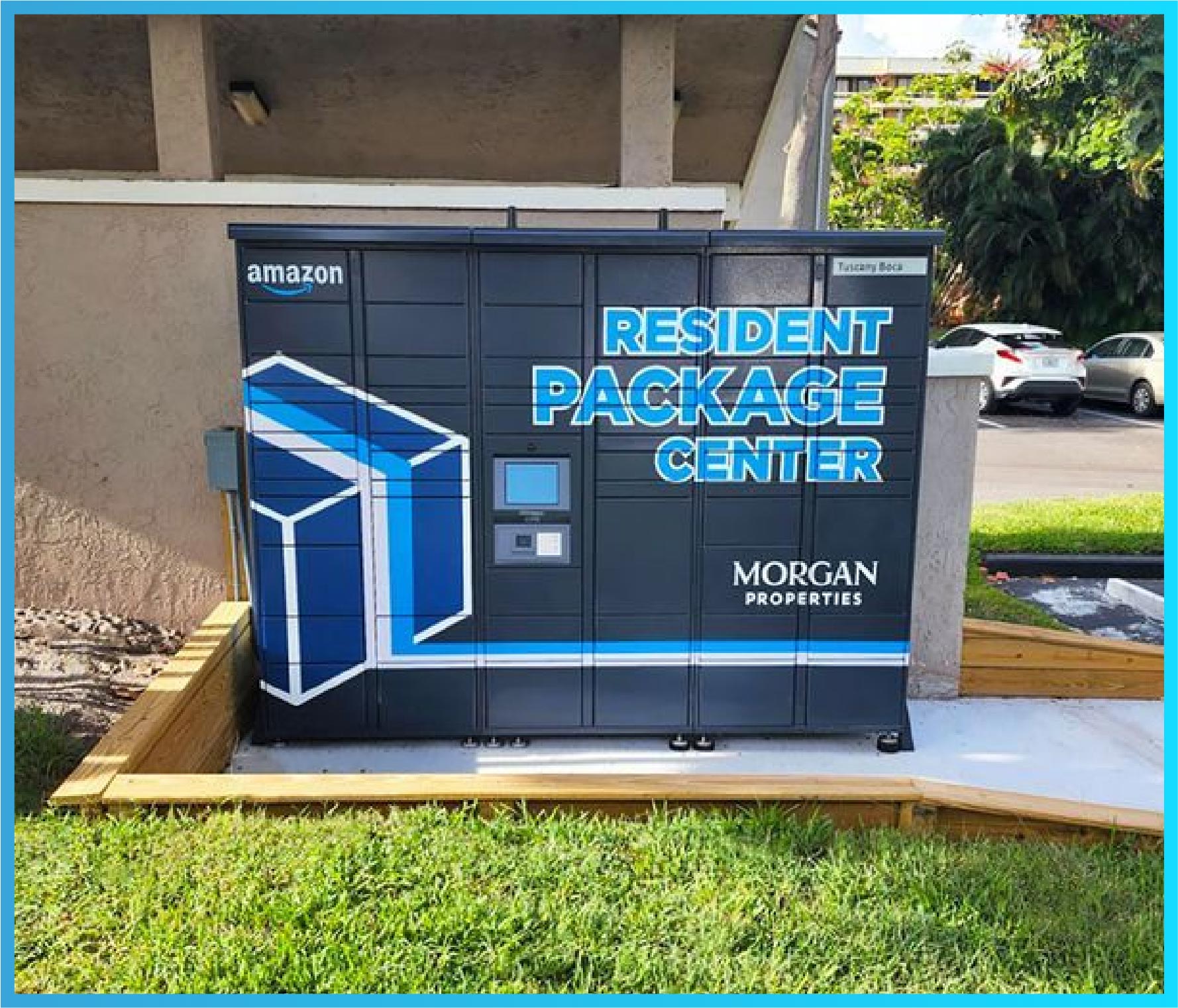

Precise service - industrial scene customization platform

__________

Equipped with multiple interactive functions and data dashboards, it fits the production and logistics scenarios of the factory, meets the personalized sending and receiving rules and material circulation needs of enterprises, and promotes the digital transformation of the park.

Scenario-based customization: adapt to different scenarios such as workshop picking, supplier delivery, and employee personal parts.

Quick response to demand: Flexible adjustment of sending and receiving rules and support for temporary material expedite channels.

Digital transformation: From traditional manual transmission and reception to intelligent systems, visualization of cost reduction and efficiency improvement.